Welcome to the future of Maintenance.

Connect - Collaborate - Manage - Plan - Execute

The user interface of the future for the workforce will be visual, analytical, interactive and adaptive where it makes sense, offer new ways to visualise problems and solutions, and enhance collaboration.

The right work gets done, at the right time, with the right tools, materials, and people.

- Maintenance Project Management

- Turnaround / Shutdown Maintenance (STO)

- Decommissioning

- Inspection Planning

- FLAB Planning (Fasteners, Lubrication, Alignment, and Balancing)

See the Big Picture.

And all the details.

The platform to Manage, Plan, Execute and Optimise your Maintenance Project.

Connect teams, tools, data and process to get insights, scale your maintenance program.

Break down silos with a holistic view

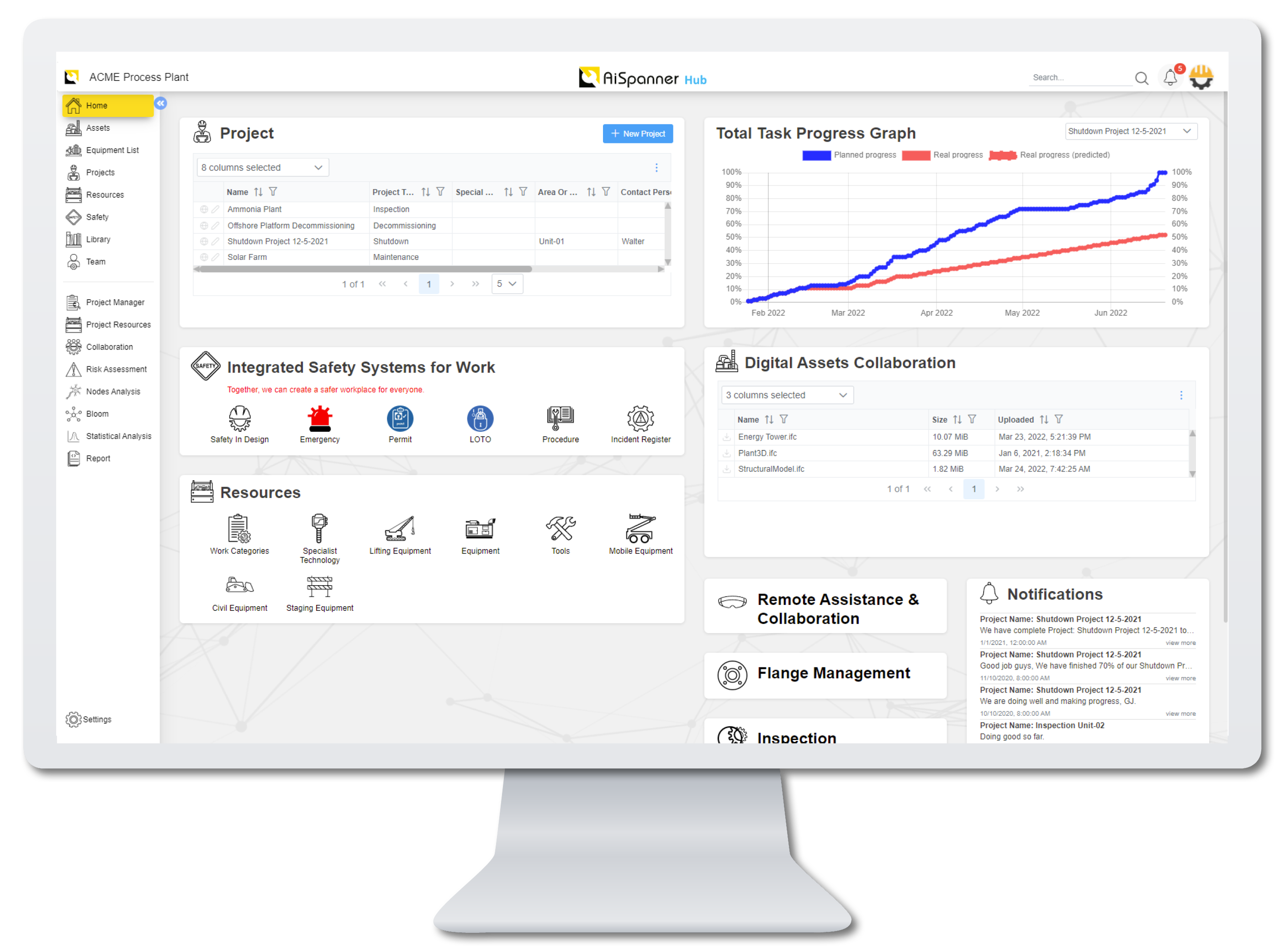

AiSpanner is a maintenance lifecycle management solution that gives every stakeholder the tools and real time information they need to run maintenance efficiently and effectively.

Time and data are one of the most valuable assets in maintenance projects. Our connected data centric approach creates a digital thread across the project functions that allows planning, scheduling, monitoring, tracking, analysing and integrating digital assets. With all stakeholders on the same platform, you can seamlessly and efficiently communicate across all different interfaces.

AiSpanner platform is a "single source of truth" that supports information sharing amongst stakeholders for the maintenance lifecycle, increase data quality, control and compliance for streamlined digital work processes.

Safety requirements, standards and historical incidents related to the project are available to all stakeholders in AiSpanner's platform.

AiSpanner can track project or portfolio progress in real time on the dashboard. Get advanced visualisation and analytics that automatically calculate costs, health and other metrics for each stage of project. Empower organisations to visualise each layer of their maintenance project and their interdependencies.

AiSpanner's cloud native platform powers all the capabilities you need to rapidly deliver new connected solutions at scale. Built on leading cloud services, AiSpanner provides you with the security and scalability your business requires.

Common Platform for all stakeholders

Project Storyboard

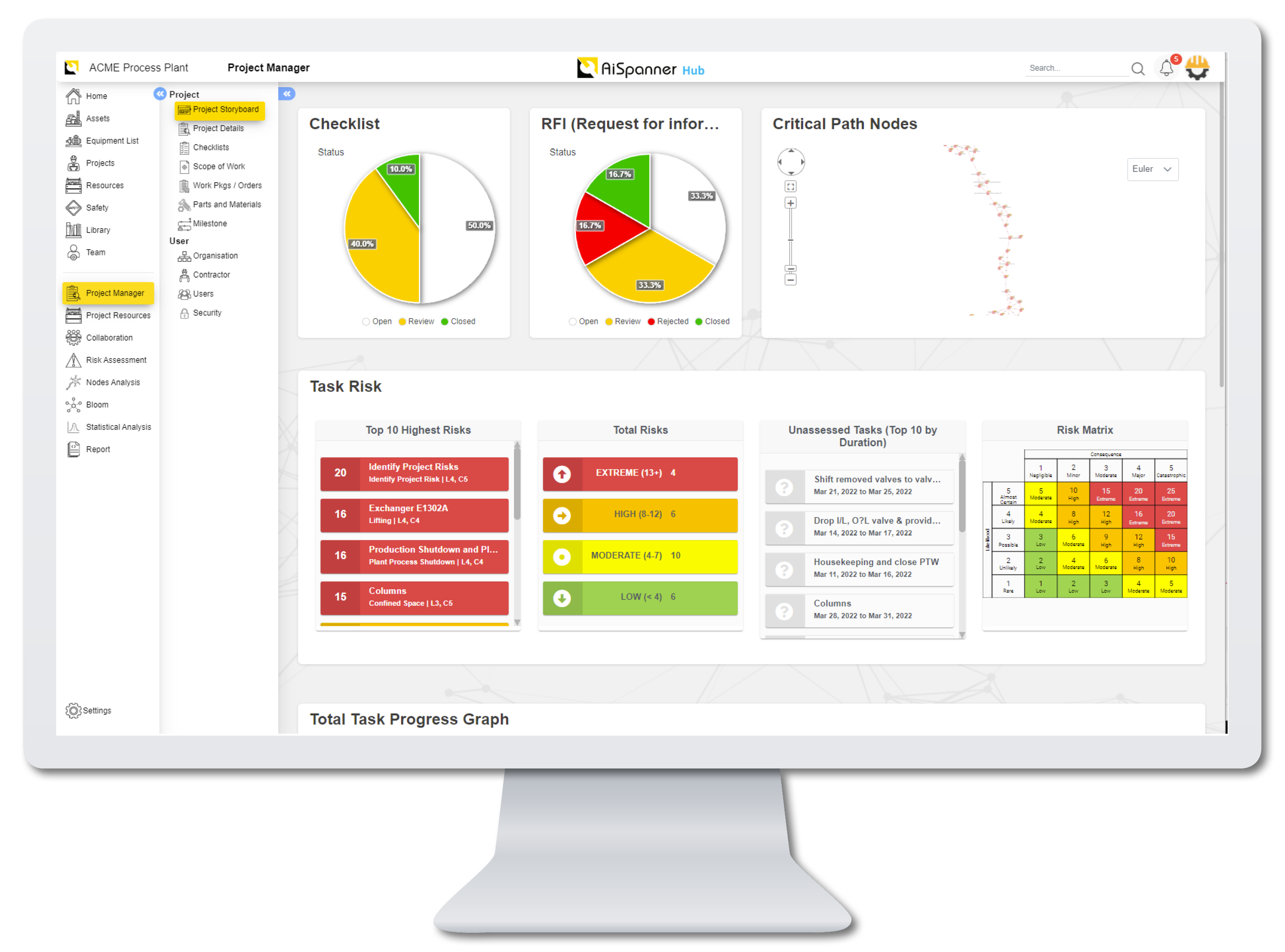

Intelligent, analytical and KPI driven

Provide project owners, stakeholders, and leadership a robust, real-time view into the status of top KPIs, critical trends, and summary.

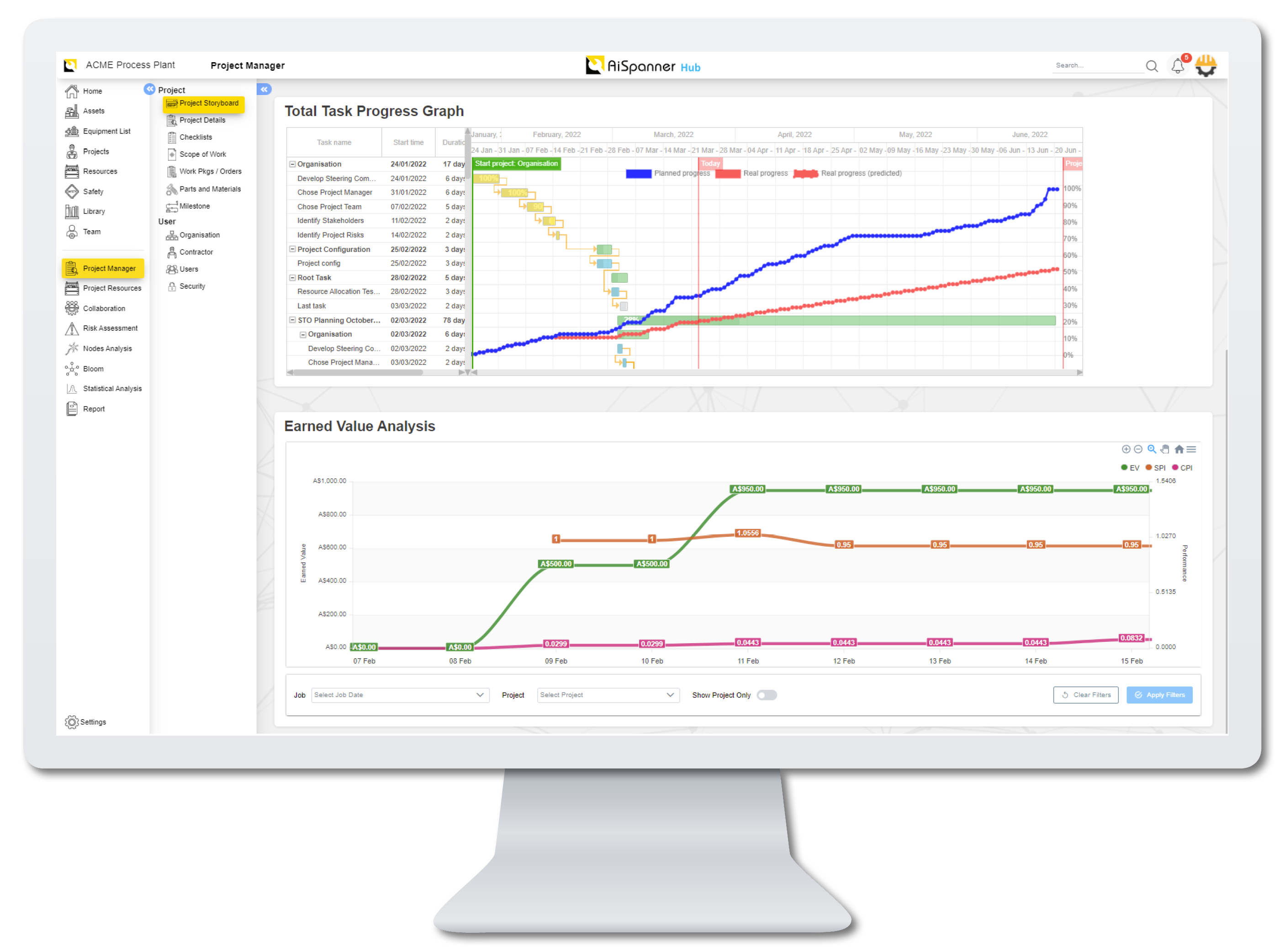

Centralised Project Schedule

Keep projects on track with Connected Real-time access

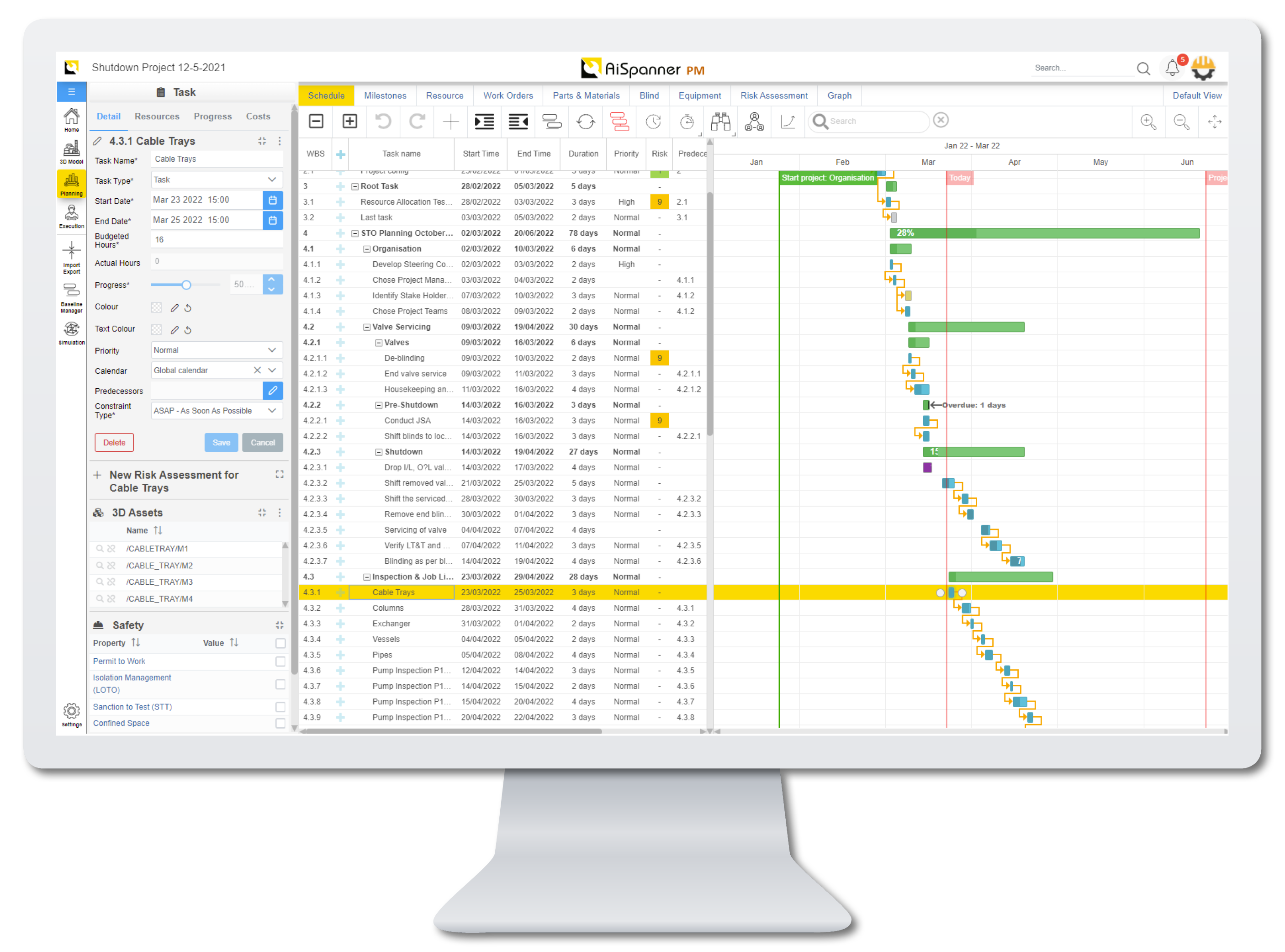

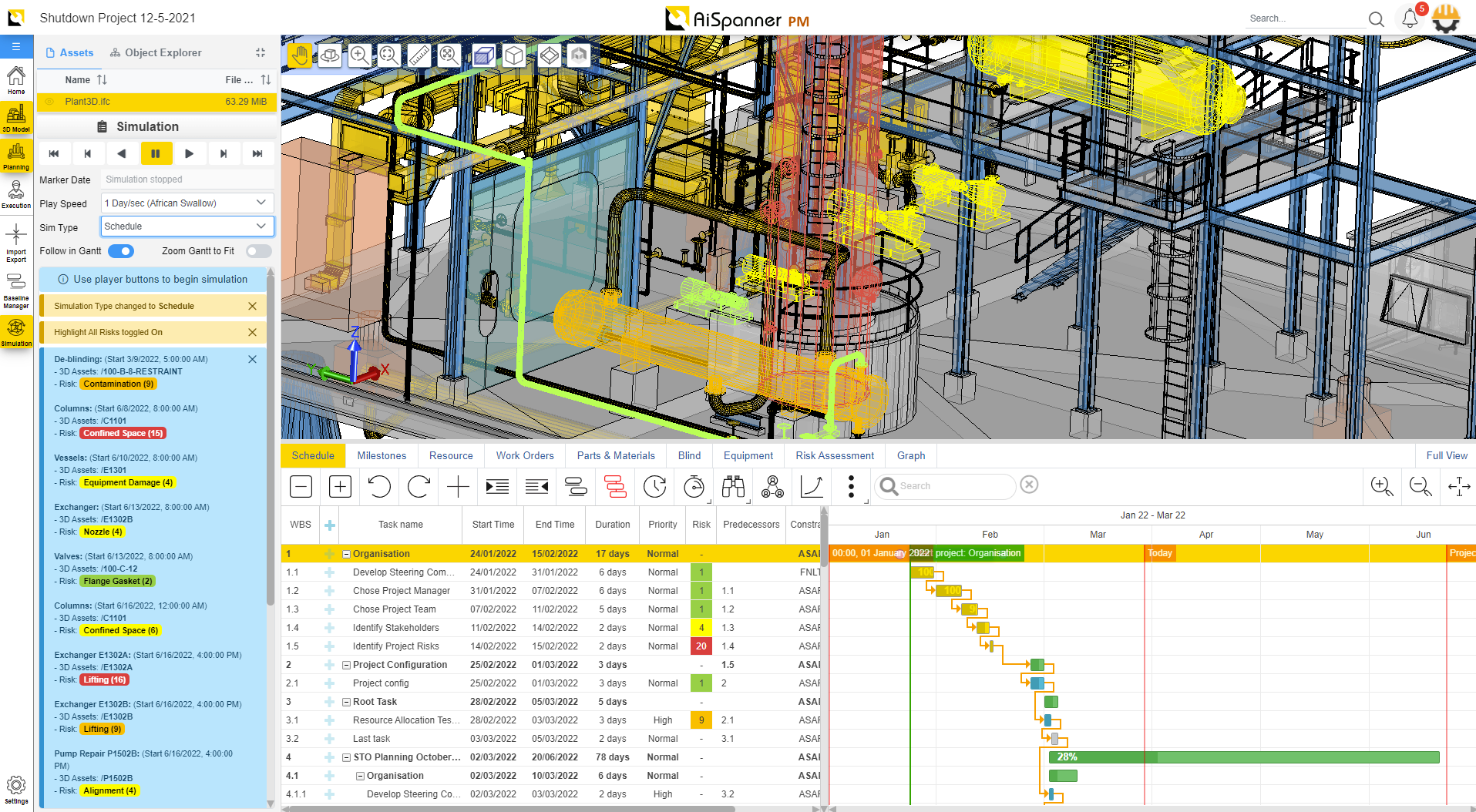

AiSpanner's maintenance project management system combines, powerful project planning and scheduling features with collaborative tools for teams. Makes planning easy, with intuitive scheduling, 3D model integration, risk and resources management features for improved project outcomes.

AiSpanner's graphical user interface enables users to enter domain specific scheduling knowledge and requirements quickly and easily. Interactive graphical displays enable users to visualise and edit the schedule's resource allocations and temporal relationships among activities.

Developed from ground up to take advantage of emerging technology like advanced Visualisation, Cloud computing, Mobile technology and graph database, it connects all project data with relationship context.

Data Storytelling

Helping you see the unseen

Spatiotemporal

Space and time analysis for schedule, risk, cost and progress with dimension.

Nodes

Knowledge graph analysis for critical path, resources, risk and interactive investigation.

Statistical

KPI, critical trends with earned value analysis (EVA) and Monte Carlo Analysis.

AiSpanner transforms your data into consumable, contextual & actionable knowledge and drives continuous decision intelligence

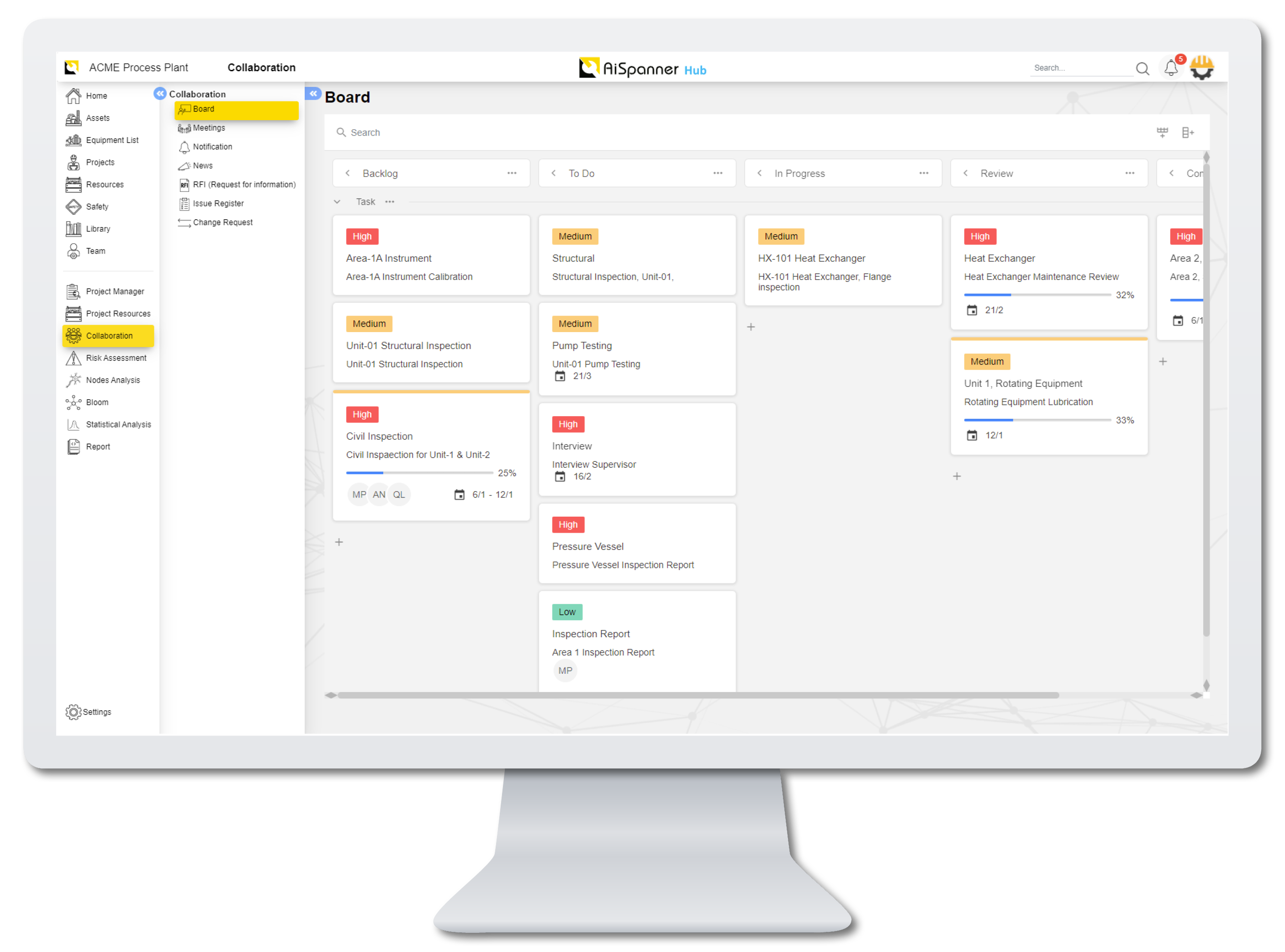

Inefficient communication between project stakeholders is one of the root causes of project failures, and as project size and complexity grow, so do the communication challenges. AiSpanner's communication & collaboration address these challenges.

End-To-End Collaboration

A simple but powerful real-time team collaboration tool that has everything built natively inside. Document project risks and create an action plan to mitigate them.

Manage issue register, project change request and RFI as they emerge.

In the planning office or at the jobsite, our common collaboration platform, data and analytics bring teams together to increase safety and productivity.

Connected stakeholders, data and workflow simplify collaboration at every stage of projects.

Key Benefits

- Improve worker and asset safety

- Single Source of truth (Breaking Silos: Data, Application, Workflow)

- Better visibility and continuity across the lifecycle for improved governance and risk mitigation

- Real time cross business collaboration improves project productivity and increases knowledge reuse

- Data integrity & improved accuracy

- Better capitalisation of knowledge and best practices

- An Interactive analytics experience

- Reduce Waste, Cost and minimise risk

OFFICE

300 Murray Street, Level 2 East,

The Wentworth Building,

Perth WA 6000

Australia

Process Plant

Process Plant

Mining

Mining

Hydrogen

Hydrogen

Wind Farm

Wind Farm

Solar Farm

Solar Farm